旋轉(zhuǎn)噴射器的安裝說明

目 錄Orders to record

二,、結構特點Structural characteristics of

三、主要規(guī)格參數(shù)Main specification parameters

五,、安裝說明Installation instructions

六,、使用操作說明Operating instructions

一、概述Overview

本旋轉(zhuǎn)噴射器主要用于重質(zhì)油品和輕質(zhì)油品的儲罐噴射調(diào)合作業(yè),,對儲罐內(nèi)部進行旋轉(zhuǎn)噴射,,采用直噴加渦流方式,使油罐內(nèi)部介質(zhì)充分混合,,起到均質(zhì)均熱的作用,。

The oil tank with full blending machine, mainly used in heavy oil and light oil tank injection industry cooperation, to rotating inside the tank, adopts direct injection with eddy current method, make fully mixing tank internal medium, homogeneous.

二、結構特點Structural characteristics of

油品旋轉(zhuǎn)噴射器主要由驅(qū)動主體,、旋轉(zhuǎn)噴射主體,、噴油嘴組成。驅(qū)動主體與進油管相連接,,豎直置于油罐的底部相應位置,利用進油管的油品流過的動力,,使油品儲罐用全方位調(diào)合器旋轉(zhuǎn),。噴油嘴內(nèi)部設置有助力螺旋漿,使得油品從噴嘴口360度旋轉(zhuǎn)噴出,,對儲罐內(nèi)部進行全方位噴射,,作用力強、不留死角,。

The oil storage tank is mainly composed of drive main body, rotary jet main body and spray nozzle. The driving body is connected with the inlet pipe and is placed vertically at the bottom of the tank. The fuel flow through the oil can be used to rotate the oil tank in an all-round way. The internal setting of fuel injection nozzle has the help of propellant, so that the oil can be spun out from 360-degree Angle of nozzle, and it can be sprayed all over the tank, with strong force and no dead Angle.

三,、主要規(guī)格參數(shù)Main specification parameters

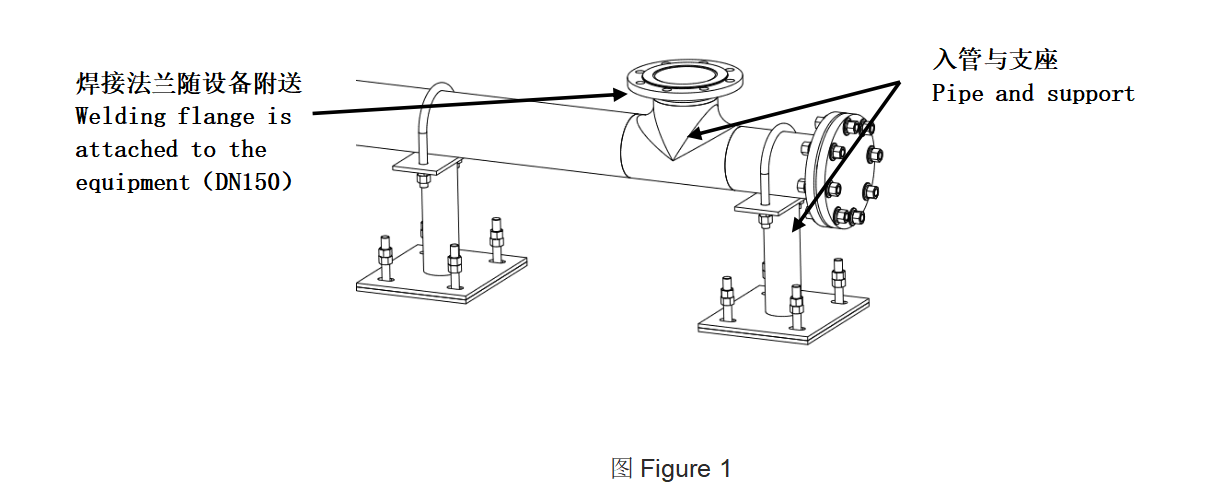

設備入口法蘭規(guī)格:DN150 (HG/T20592-2009 PN25 RF)

配套焊接法蘭規(guī)格:DN150 (HG/T20592-2009 PN25 RF)

設備外形尺寸: 長×寬×高 520×520×410毫米

Equipment inlet flange specification: DN150 (HG/T20592-2009 PN25 RF)

Welding flange specification: DN150 (HG/T20592-2009 PN25 RF)

Device dimensions: long * wide x 520 x 520 x 410 mm

四、注意事項Precautions

在整機運輸時請注意平放輕移,,開箱時從上往下拆卸,,塑料包裝膜在非裝配時不要打開。

Please note that when the machine is transported, remove the flat and remove from the top. The plastic wrap should not be opened during non-assembly.

現(xiàn)場整機裝配時,,必須整機與儲罐對號安裝,,同箱拆出的噴嘴與旋轉(zhuǎn)噴射主體按照標識碼對號裝配。

When the machine is assembled on site, the machine must be installed with the storage tank, and the nozzle and the rotating jet body will be assembled according to the identification code.

整機設備在儲罐內(nèi)裝配完成后,,如長時間不用,需用塑料包裝膜防潮,,長時間停用后再次投用,需拆開檢查,,并用手對入口葉輪進行盤車處理,,至少20圈。

Machine equipment in the storage tank assembly is completed, such as long time need not, need plastic packaging film moistureproof, putting-in-service proactively again after long time stop, need to disassemble, with the hand to turning the impeller entrance, at least 20 laps.

五,、安裝說明Installation instructions

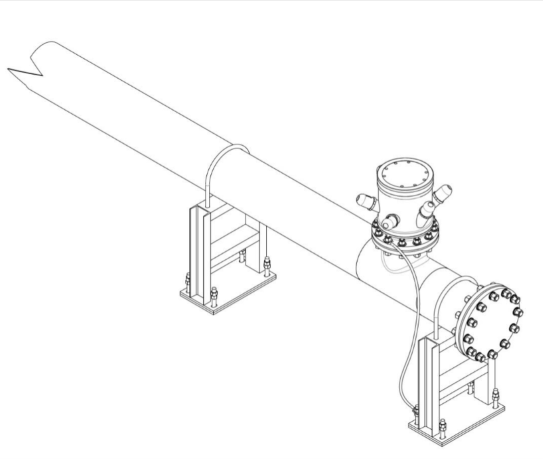

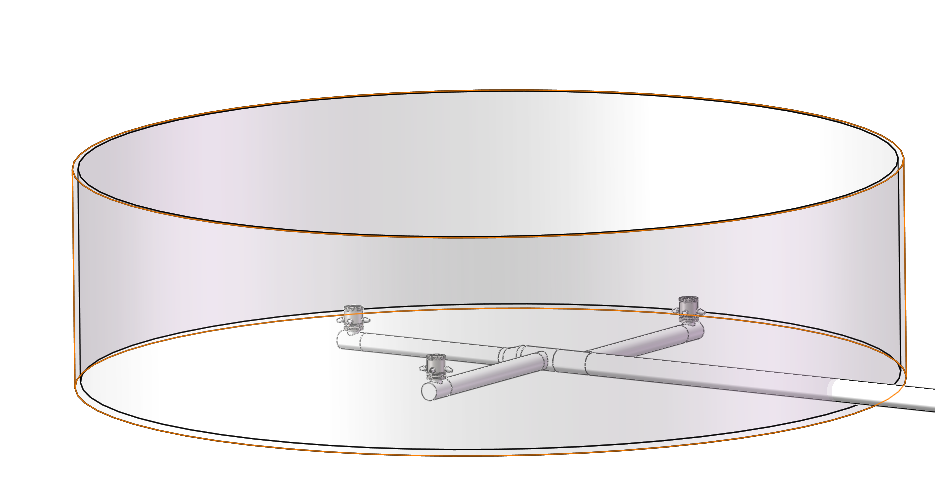

見圖1將入管與支座與彎頭在罐內(nèi)焊接到指定位置,。入管與設備法蘭不符時可用變徑管處理。See fig.1 to weld the tube and support and elbow into the designated position in the tank. When the tube is not in accordance with the equipment flange, it can be treated with reducer.

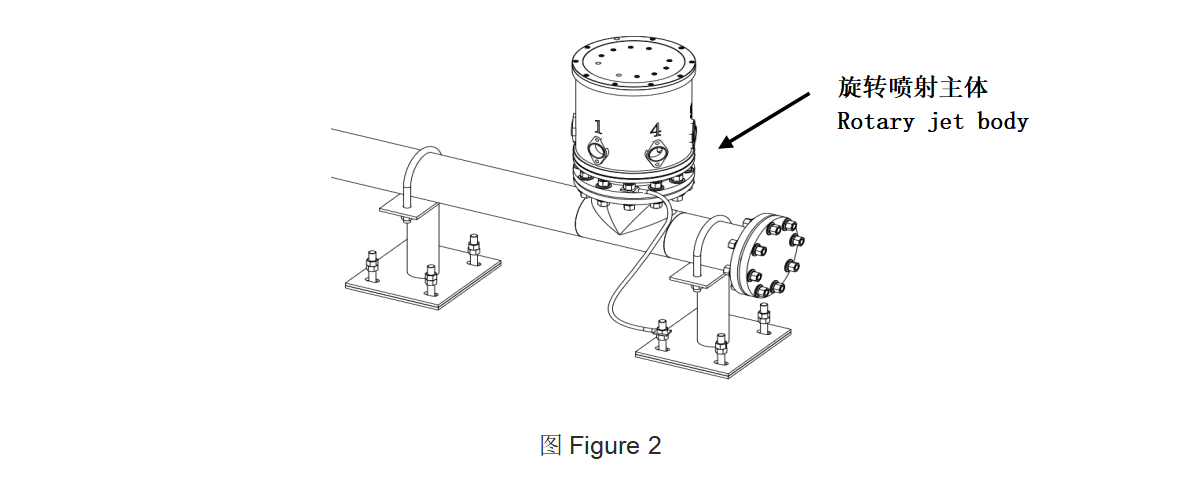

見圖2將旋轉(zhuǎn)噴射主體安裝在彎頭法蘭上,。

(隨設備帶有配套螺栓)

See figure 2. The rotating jet body is installed on the elbow flange.

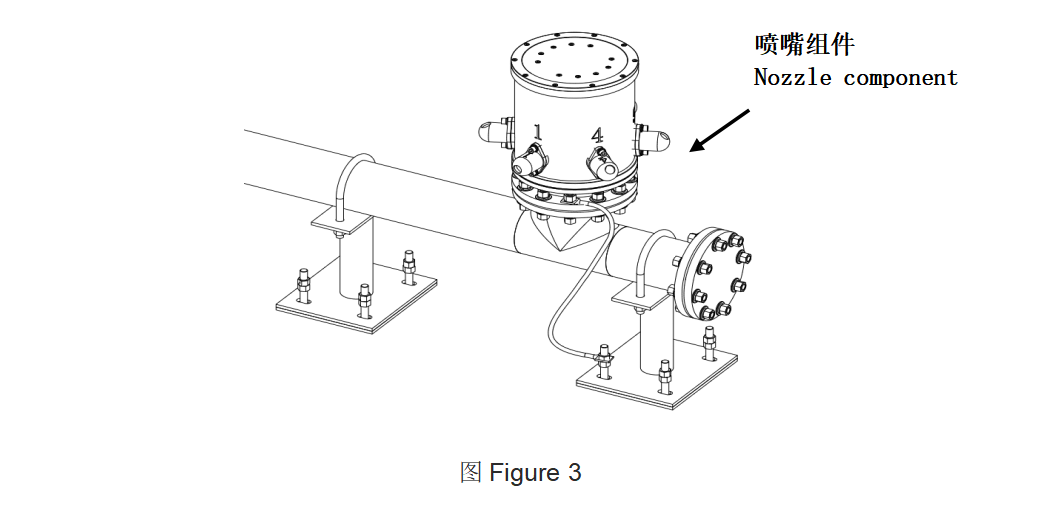

見圖3將噴嘴安裝在噴射主體上,。

(隨設備帶有安裝噴嘴的專用工具及螺紋密封膠,,每個噴嘴體上都有相應號碼,安裝時必須對號裝配)

注:圖示為6個噴嘴示意圖,,操作時按實際產(chǎn)品的噴嘴數(shù)量,,對號裝配完整。

See figure 3 to install the nozzle on the jet body.

(with the equipment with special tools and thread seal, each nozzle body has the corresponding number and must be equipped with the right number when installed).

Note: the picture shows six nozzles. The number of nozzles in the actual product is complete according to the number of nozzles in the actual product.

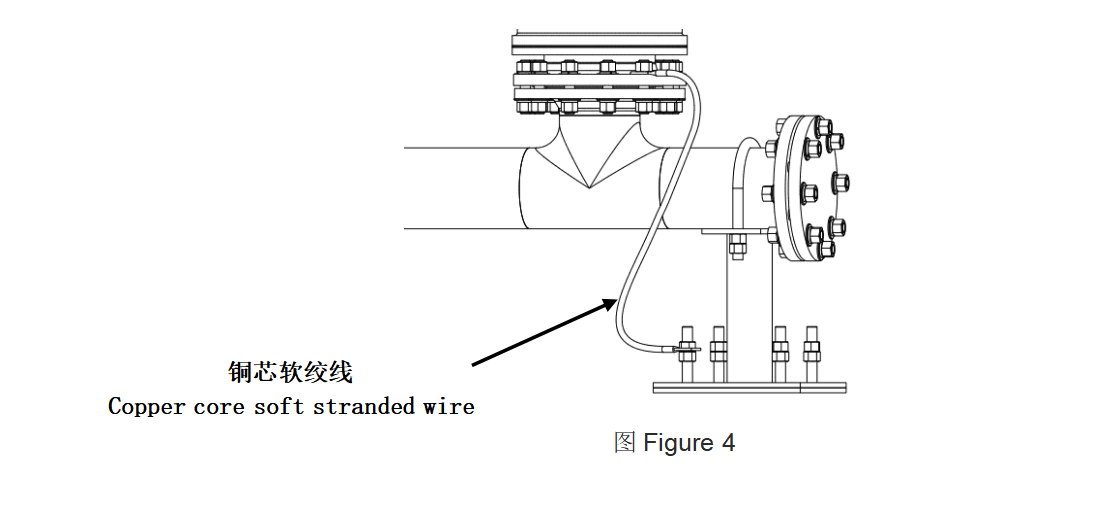

靜電接地線的連接

靜電接地線采用截面積不小于25mm2的銅芯軟絞線連接,。

Connection of electrostatic grounding wire

The electrostatic grounding wire is connected with a copper core with a cross-sectional area not less than 25mm squared.

六,、使用操作說明Operating instruction

油品儲罐用全方位調(diào)合器開啟時必須保證一定的安全液位,拱頂罐的安全液位是浸沒設備1500mm,。外浮頂或內(nèi)浮頂儲罐的安全液位是:設備安裝高度(≤1200mm)+浮盤支腿長度+保障液位(≥1500mm),。

操作流程:罐內(nèi)油品不低于安全操作液位時,開啟循環(huán)調(diào)合泵,,油品通過管道到達罐前閥時,,全口徑開啟罐前閥,油品進罐后,,即可通過噴射式全方位調(diào)合器,,進行調(diào)合作業(yè),這時罐內(nèi)油品象油品開鍋時的情形,,不規(guī)則運動,,在運動中實現(xiàn)均質(zhì)化。

通過一定時間的運行(可以不足2小時/次,,,但要根據(jù)具體情況進行摸索),,即可將罐內(nèi)油品調(diào)合均質(zhì)。

停泵后,,靜置20分鐘以上,,即可對罐內(nèi)各點采樣分析。

旋轉(zhuǎn)噴射攪拌器主要對罐內(nèi)油品實現(xiàn)均質(zhì)的作用,,若罐內(nèi)各點采樣分析均質(zhì)度達到油品性能要求,,設備即為合格,滿足功能需要,。

The oil storage tank must ensure a certain level of safety in the opening of a full range of recombinators. The safe liquid level of the vault can be 1500mm immersion equipment. The safety level of the outer floating roof or inner floating roof tank is: the installation height of the equipment (≤ 1200mm) + the length of the floating disk and the guarantee level (≥1500mm).

Operation: tank oil not under safety operation level, open loop blending pump, oil reached before the tank through a pipeline valve, valve before full aperture open cans, oil into the pot, can through the jet mixing apparatus in all directions, adjusting industry cooperation, the tank of oil as oil boiled, irregular movement, realize homogenization in the movement.

After a certain period of operation (it can be less than 2 hours/time, but depending on the specific situation), the tank can be adjusted to homogeneity.

After the pump has been stopped, sit for more than 20 minutes, then sampling and analysis of each point in the tank can be analyzed.

Rotary jet all-round main of tank oil blending device to realize the uniform, if the tank each point sampling analysis of homogeneous degree meet the requirements of product performance, equipment is qualified, meet the needs of the function.

Shandong Hengran machinery manufacturing co. LTD